Pharma

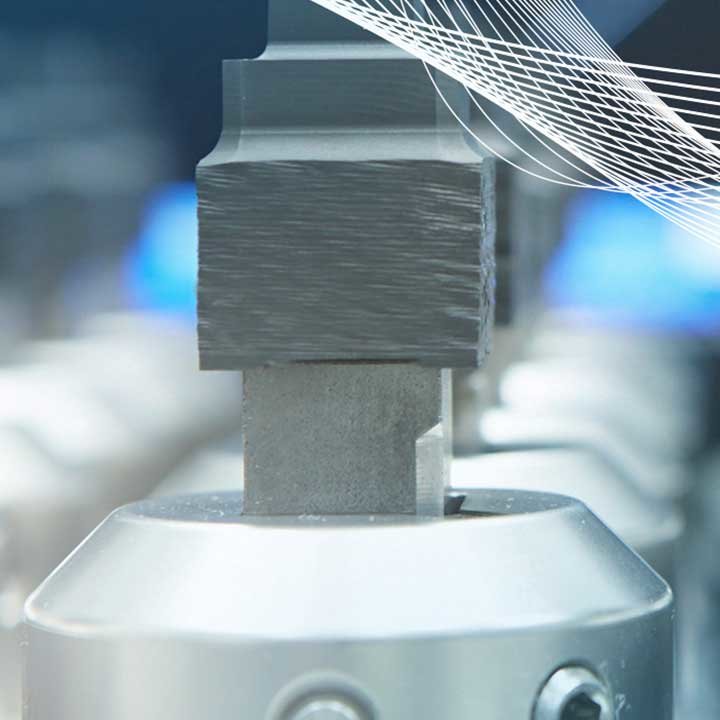

Cleanroom injection molding at the highest level – MED Mold® from Braunform

Injection molding in cleanrooms requires maximum precision and uncompromising quality in mold making. With over 30 years of experience in the pharmaceutical and medical market, Braunform has bundled its comprehensive expertise into its proprietary MED Mold® standard. Since 2011, this standard has stood for maximum process reliability, cleanroom compatibility, and technical excellence.

By combining pharmaceutical know-how and innovative technology, Braunform guarantees low-contamination production of plastic articles with its injection molding tools. A unique feature of mold making is pharmaceutical technology production in our own cleanrooms in accordance with GMP C and D. This and our MED Mold® standard are our quality promise to demanding customers in highly regulated industries.

Drug Delivery Systems

- Respiratory inhalation systems

- Oral sprays and sprayer systems

- Ophthalmic / otologic and nasal sprays and dispensing systems

- Injection & safety devices

Medical & Laboratory Devices

- Port systems

- Components of infusion systems: stop-cock, flowcontroller

- Diagnostic requirements: test tubes, well-plates, other laboratory requirements

- Medical closures

Technology

Craftsmanship combined with perfectly mastered technique enables us to achieve top performance in all areas of plastics technology.

About us

As a leading mold maker, Braunform stands for technical excellence, sustainable practices, and collaborative partnerships.

Trade fairs & Events

Always be informed in which direction Braunform is developing and visit our regular events.