K 2013 fair - innovative mold technolgy

Braunform MED mold®

02.09.2013

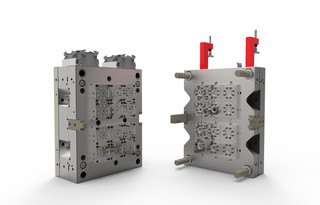

Innovative mold for high-volume expertise - Braunform MED mold® combines process-safe pharmaceutical technology with a 96-cavity high-speed injection mold at K 2013 Show in Dusseldorf /Germany

At the K 2013 show from 16th to 23rd October 2013 in Dusseldorf / Germany Braunform will present a high cavitation injection mold according to Braunform MED mold® standard with a very short cycle time (about 5 seconds) together with the project partners Hekuma and ENGEL. The 96-cavity mold for a pen stroke (needle holder) is designed according to Braunform MED mold® standard (standard developed especially for injection molds in cleanrooms) and is based on the long-standing expertise of the mold maker in the pharmaceutical technology.

The high cavitation injection mold processes the article in a highly automated manufacturing cell under constant visual monitoring. With cores with a diameter of only 0.3 mm and 0.5 mm the tool is designed according to the latest state of the art. Special attention in the development of the mold was placed on the modular design i.e. the modules are individually centered and (de)mounted externally accessible. Furthermore, the mold cooling is developed to achieve shortest cycle times, amongst others with vakuum brazing. Also worth mentioning is the direct side gate of the article with a full hot runner brand Heitec.

For the implementation of the complete project the automation specialist Hekuma has developed the high-speed extraction with an acceleration of up to 17G and a camera surveillance system for automatically sorting out rejected articles in case of breaking cores in the mold. The machine manufacturer ENGEL provided a fully electric ENGEL e-motion 220t. Also involved in the realization of the injection mold are the mold shop partners Meusburger, HEITEC and Listemann.

During the exhibition period, the injection mold will be exhibited at the booth of ENGEL. The corresponding module inserts are shown at the booth of Braunform in Hall 1, Stand F30 in detail.

The machine manufacturer Ferromatik Milacron GmbH shows on its booth a 4-cavity injection mold for the production of a 1 component container of the product "Adapplicator®". The cycle time of the tool is 9 seconds, the part weight is 1,6 g.

This mold is characterized for its hot half being used for two items: the 1ml Adapplicator® as well as the 2ml Adapplicator®. The modular unit - in detail the cavity plate nozzle side and the complete ejector side – can be changed while the hot half remains on the injection molding machine. The tool has a modular structure, in which the mold inserts can be replaced on the nozzle side. The mold plate must not be changed. This removal may take place on the injection molding machine which has the advantage that the mold does not have to be removed from the machine during maintenance or cleaning processes.

The Adapplicator® or "the spraying vial" for mucosal and topical application in human medicine, veterinary medicine and wellness is used by many doctors, naturopaths and chemists.

Contact Person

Marketing

Tel. +49 (0) 7663-9320-0

marketing@braunform.com